About me

I am a control system researcher at Shanghai Nuclear Engineering Research and Design Institute (SNERDI). I received the Ph.D degress in Control Science and Engineering from Shanghai Jiao Tong University. I was a visiting scholar in University of Oxford when Pursuing Ph.D. I received the B.Eng. and M.S. Eng. degrees in Automation from North China Electric Power University in 2016 and 2019, respectively.

I am focusing on modeling, safety-critical and optimal control of the nuclear power engineering. Moreover, I dedicate to applying these techniques to Digital-Twin Systems for industry and industrial robotics in my free time.

What i'm doing

-

Safety-Critical Motion Plan

Guarantee the safety and optimality of the motion plan.

-

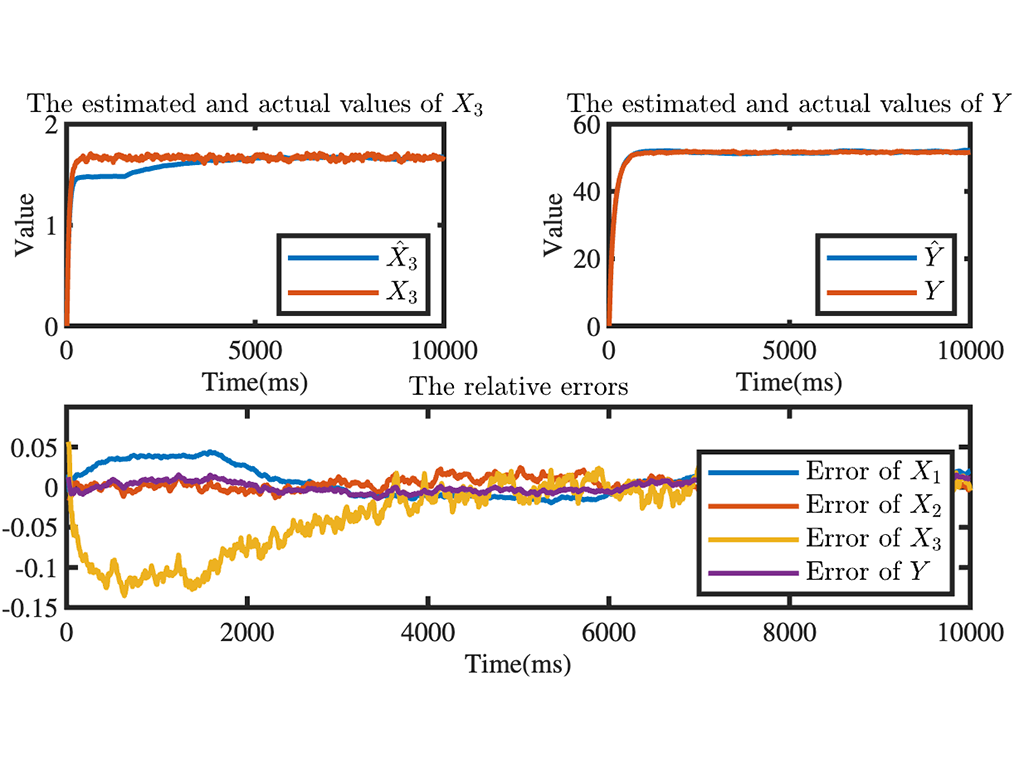

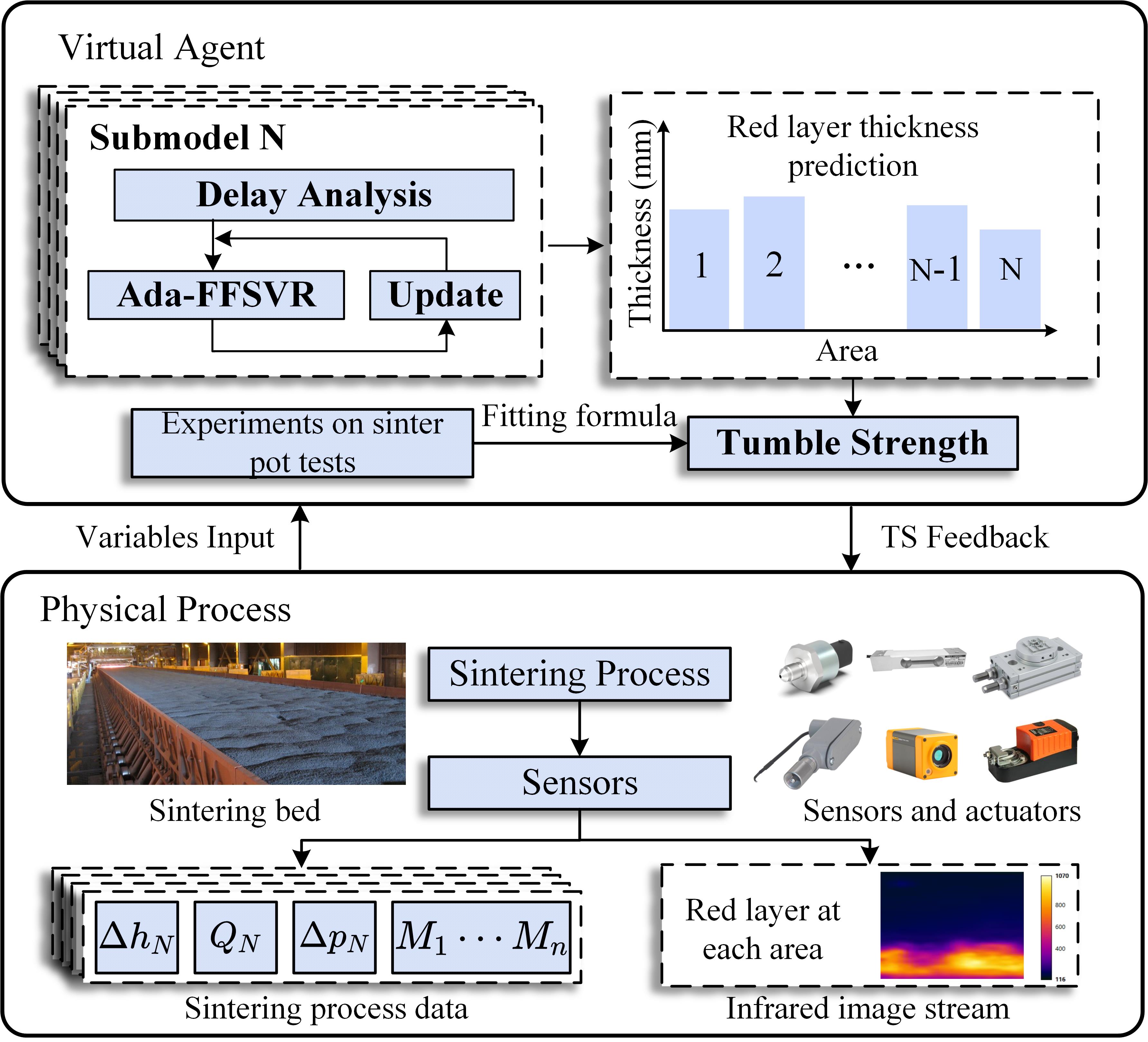

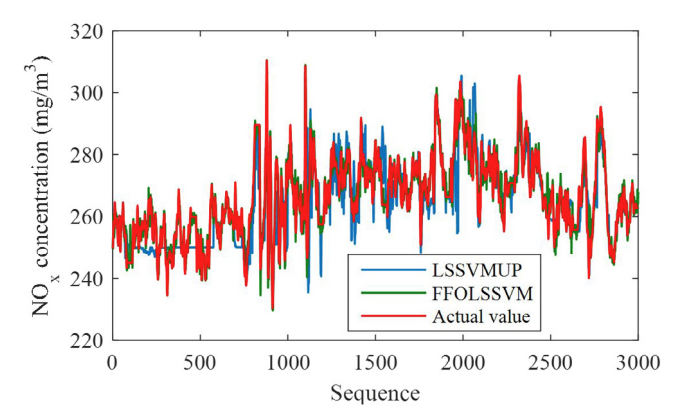

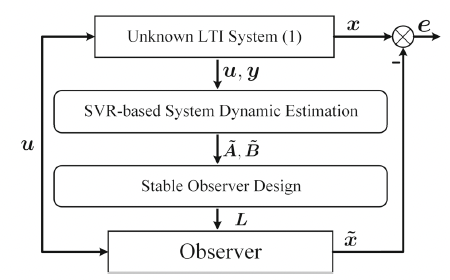

Data-driven Modelling

For virtual sensors, predictions with accuracy guarantee.

-

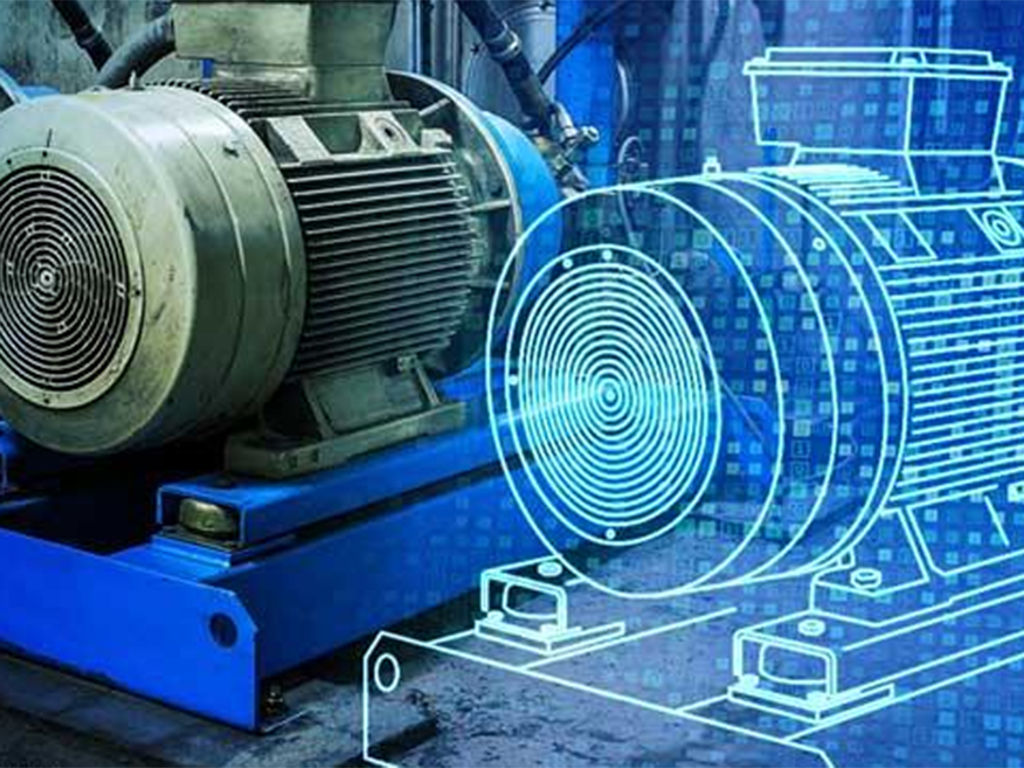

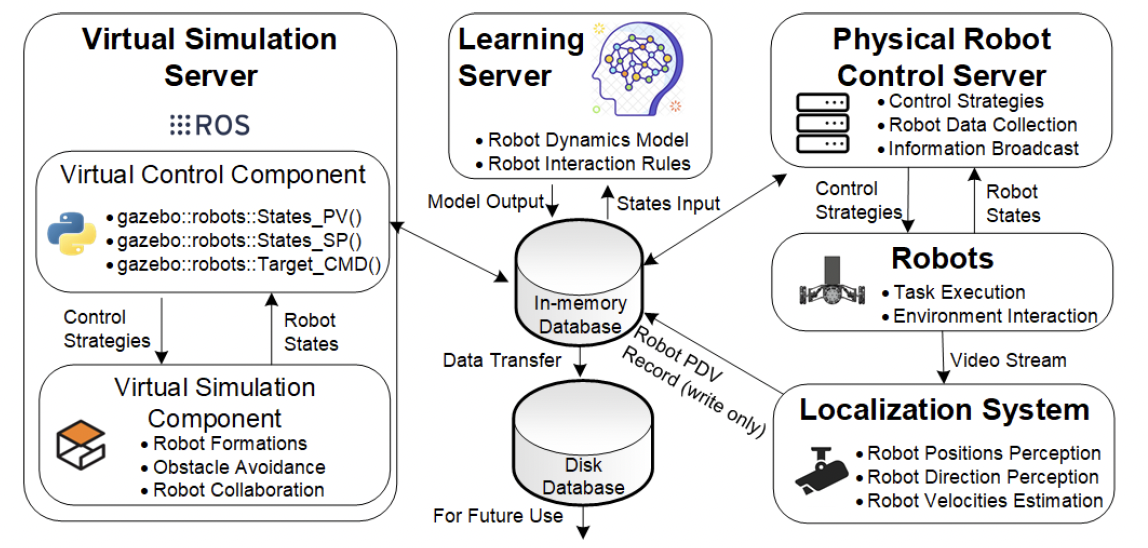

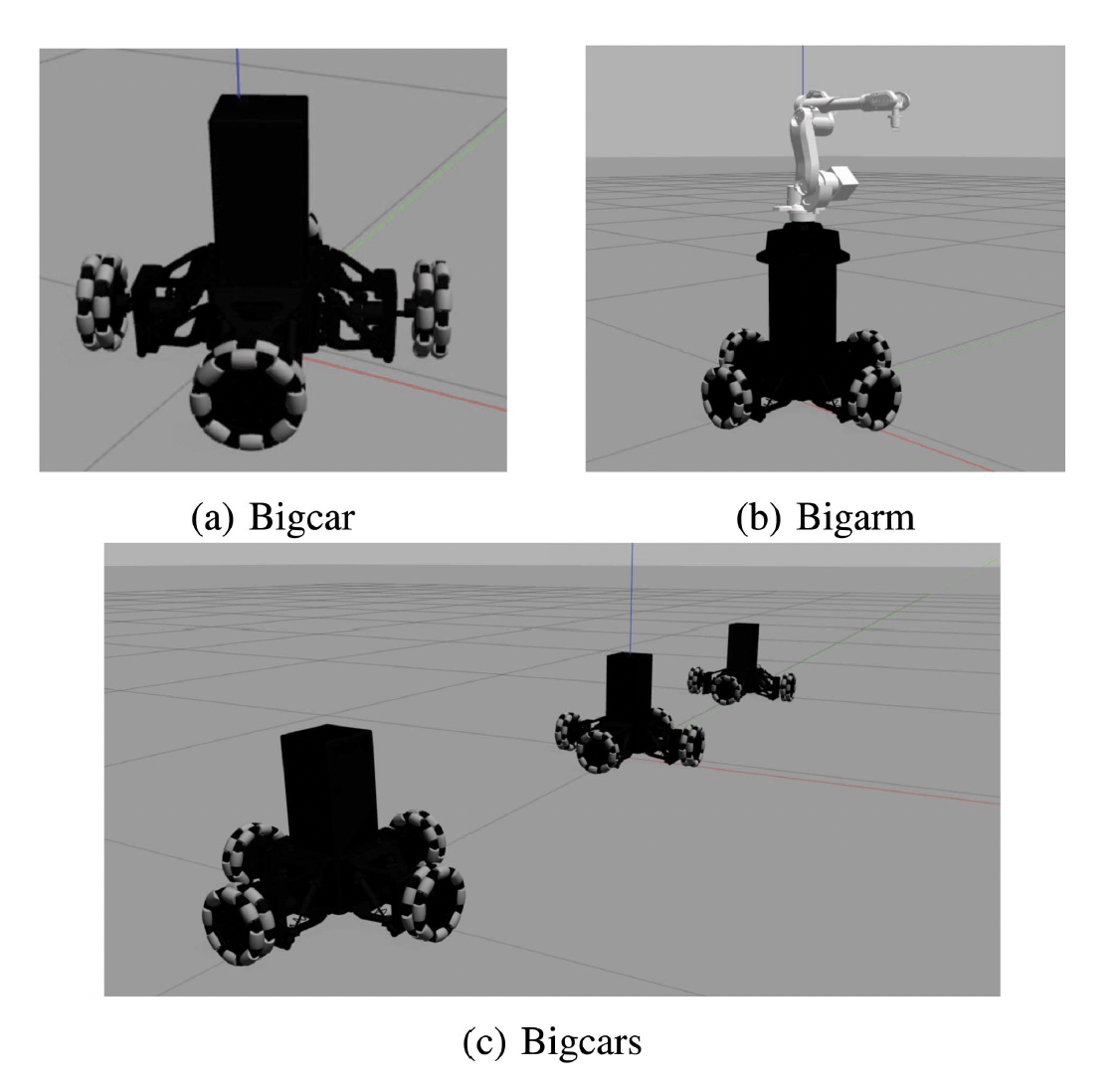

Digital Twin System

Construct digital-twin systems for industry and robotics.

-

Learning Methods in Industry

Practical applications based on learning methods.